When the seed oysters are big enough they are moved to various upwelling systems. After about a week on the setting screens the seed oysters are screened to separate them from the shell chip and are moved to upwellers.

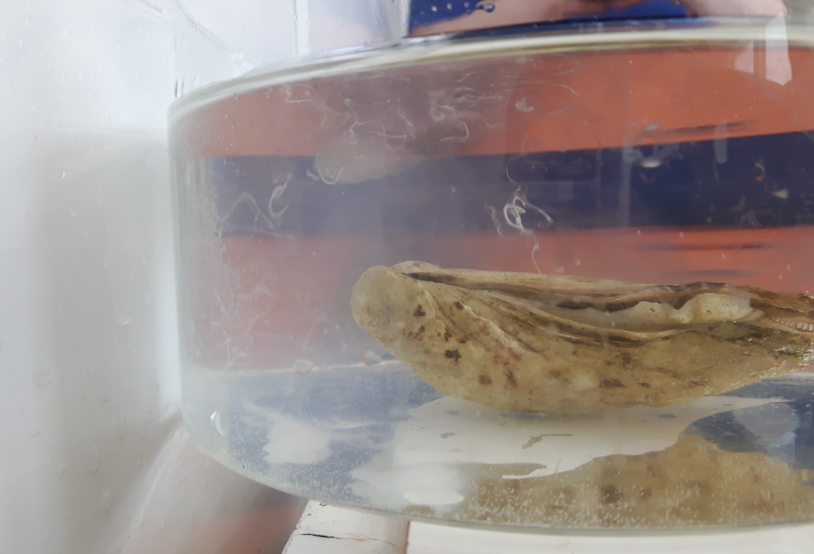

Once set, the oysters quickly begin to feed and grow as post-set juveniles, now called seed. A layer of finely ground oyster shell is spread on the screens to provide the substrate for attachment and metamorphosis. The ready-to-set larvae are placed into shallow, fine-mesh floating screens. They are now ready to undergo a metamorphosis and become a bottom dwelling, non-motile oyster. By about 14 days the larvae are held on a 200 micron (.0083”) screen and they develop two eyespots that guide them away from the light towards the bottom, and a foot that they use for crawling. At 48 hours the larvae are retained on a 50 to 60 micron screen (.0024” to. At each drain-down the larvae are restocked at the appropriate density to maintain rapid growth. The larvae are fed daily and the tanks are drained on special sieves every 48 hours to change the water and grade the larvae on sizing screens. Within 48 hours after fertilization the oyster embryos grow clear shells around themselves and a ciliated appendage which they extend from between the two shell margins for swimming and feeding. Our first spawn of the season is usually the very beginning of January, and our last is generally late June or early July. The fertilized eggs are then washed on a 20 micron screen and placed in calibrated buckets where they are counted and placed into the larval culture tanks. The females are easy to identify because the eggs have a distinctly granular appearance, and the egg basins are pooled into larger buckets where, if necessary, more sperm is added to insure good fertilization. The oysters spew their gametes into the water turning it milky. We typically sacrifice some males from the desired genetic line and add stripped sperm to the water in the basins to help initiate spawning. Ripe oysters are placed in their own basins and stimulated to spawn by rapidly cycling the water temperature. Please see our seed order form for currently-available genetic crosses. The broodstock oysters are ripened by holding them at elevated temperatures with an ample supply of food for several weeks. Broodstock conditioning typically begins late in the fall, and as the hatchery season progresses we rotate different groups of oysters through the system to ripen and spawn.

#ALGAE SPECIES FEED FOR OYSTER SPAT LICENSE#

Our triploid seed is produced naturally from tetraploid (4n) broodstock with four sets of chromosomes that are crossed with diploid (2n) broodstock. Triploid seed is sold under license from VIMS and Rutgers, as well as 4C’s Breeding Technologies, Inc therefore license fees apply to these seed. Triploids have been shown, in some cases, to grow faster than diploids and because they are sterile, their meat yield and quality tends to be better during the summer months when the diploids are spawning. We produce both diploid (2n) oyster seed which have the normal two sets of chromosomes, as well as triploid (3n) oyster seed with three sets of chromosomes. We only spawn oysters that are believed to be disease resistant, typically from selective breeding. These stocks include disease resistant oysters from the Haskin NEH® line from Rutgers University and the 4DXB line from the Virginia Institute for Marine Science (VIMS) Aquaculture Genetics and Breeding Technology Center. The way to produce disease resistant seed is to use disease resistant broodstock. We also maintain a state-approved broodstock quarantine facility which allows us to safely hold broodstock oysters from out of state. We use a variety of broodstock lines, including our own oysters grown in the Damariscotta River that we selectively breed for shape, cup depth, and rapid growth. We are investing in continual improvement of our algae culturing systems through research and development, with the goal of offering microalgae to other hatcheries. We have two culture systems, one for growing small cells that are the primary food for the young larvae, and a second, proprietary system for growing the bigger cells we feed to our broodstock, older larvae, and the young juveniles before they leave the hatchery. If the hatchery is the engine that drives the business, microalgae fuel the engine. Oysters eat microalgae (single celled plants) by filtering the cells from the water. We take pride in filling and shipping all of our seed orders on time. For over 30 years we have doggedly pursued our goals of understanding the Eastern oyster’s life cycle, and using the best available technology to reliably provide disease free, disease resistant, and naturally grown juvenile oyster seed.

The hatchery is the engine that drives our business.

0 kommentar(er)

0 kommentar(er)